RealTrac Collision Awareness System (CAS) and Personnel Monitoring (RTLS) for Underground Mine

RealTrac Underground mining – is a multipurpose system for enhancing industrial security in underground mining.

The RealTrac solution Underground Mining enables to detect positioning of personnel and mining machinery; it provides the functionality for collision awareness system.

RealTrac Underground Mining - a multipurpose system for enhancing industrial security and overall efficiency of mining operation. The system consists of the following products:

Key benefits

360 ° monitoring around a vehicle

Detecting a distance to and direction of another object with accuracy up to 1 meter

Three control zones with ability to configure them as required

The system can operate independently and also be integrated into other systems

Short payback period

Operating principle and components

The system provides a situational awareness of the environment around a vehicle; detects presence of vehicles, personnel or objects within the pre-set zones. As soon as any object, vehicle or personnel equipped by RealTrac Collision Awareness tag enters the pre-set zones, the system emits tangible, audible and visual signals.

Alerts are emitted by:

Audible warning from machinery, activation of sirens or horns

Vibro signal from a tag

Blinking of a cap lamp

Vehicle lights blinking or activation of other visual signals

The intensity of alerts can be configured depending on the control zone.

Personnel equipment

Personal tag PROD TAG 410 is a mobile equipment enabling to detect positioning of personnel regarding a vehicle with installed VBUs of the RealTrac Collision Awareness system. The tag can be embedded into cap lamp or utilized as a portable equipment.

Personal tag PROD TAG 210 is a mobile equipment enabling to detect positioning of personnel regarding a vehicle with installed VBUs of the RealTrac Collision Awareness system.

Vehicle equipment

The Vehicle Operator Display (VOD) is installed in a vehicle cabin to provide a visual assessment of the environment around a vehicle and to receive notifications about dangerous proximity.

The Vehicle Control Unit (VCU) is installed on a vehicle and is calculating the distance from a tag to a Vehicle Beacon Unit (VBU) and the motion path of a tag. While detecting the control zone of a tag, it displays data about objects in a certain zone and activates the alerting system.

The Vehicle Beacon Unit (VBU) is installed on a vehicle in amount of 4-6-8 units depending on vehicle size and configuration and enables to detect personal tags (trackers) or VBUs installed on other machinery.

Independent operation

The system has embedded software and is completely independent from other systems and data networking. If a feedback channel is implemented, the system can transmit data about the detected cases of dangerous proximity, collisions and other relevant data to RealTrac server.

This enables to make further analysis of the incidents and to form activity reports.

More about the product RealTrac Collision Awareness Order the presentation

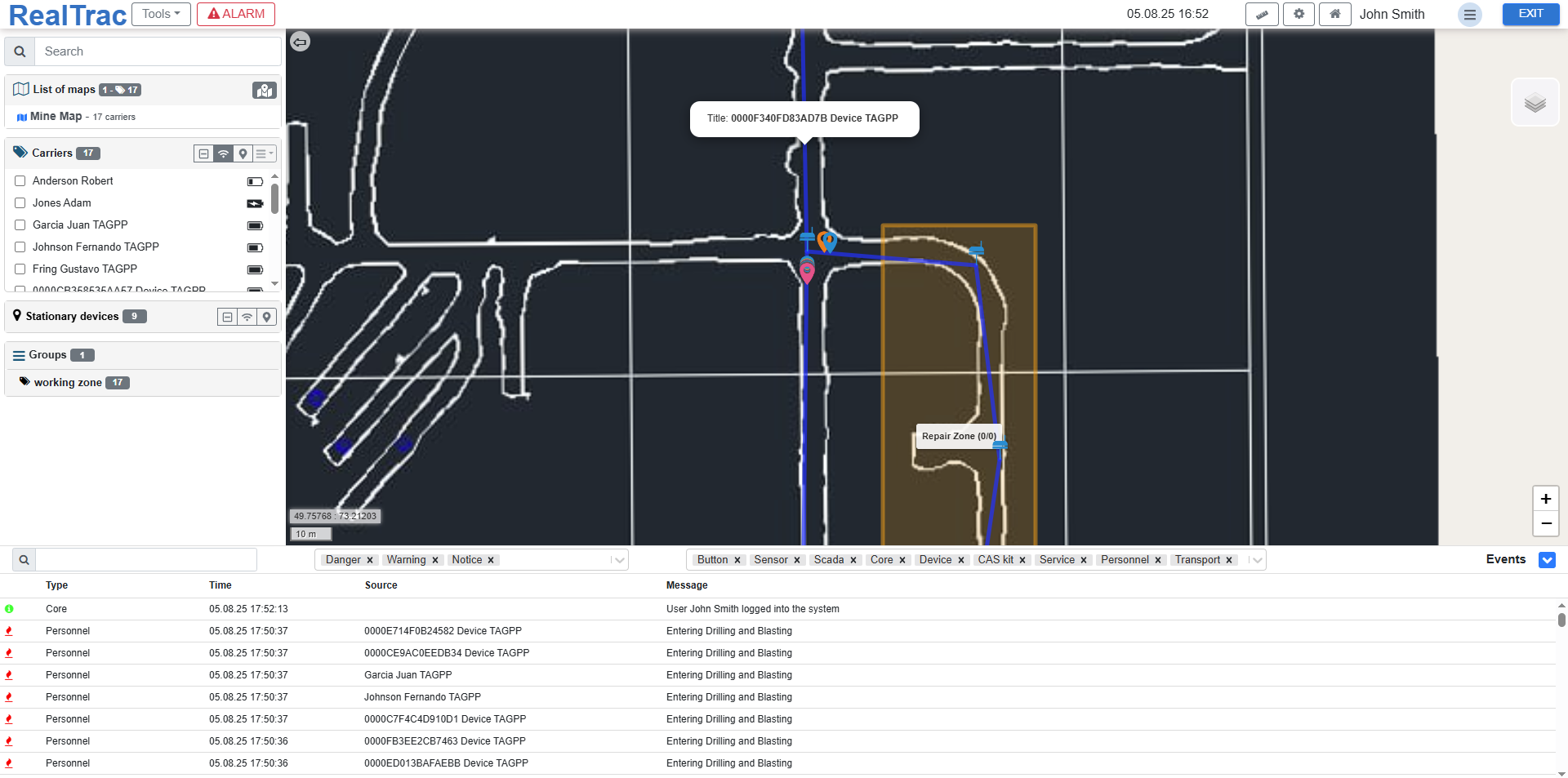

Monitoring of personnel access levels

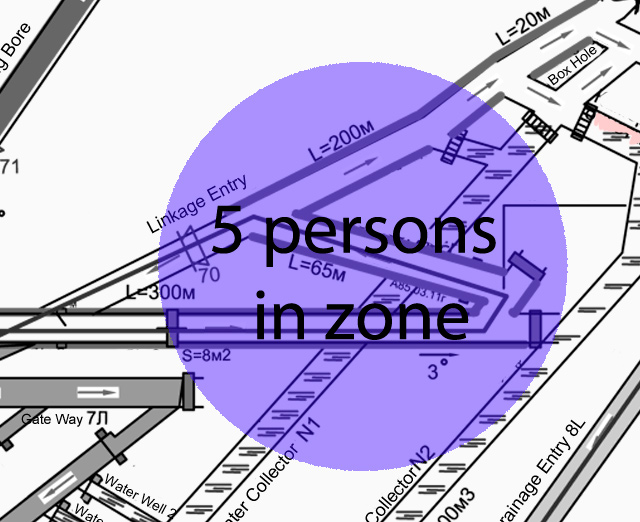

Due to geo zones with various access levels, an operator is always informed if the personnel are trespassing any forbidden zones or not. The reporting system enables to find out the access levels system violations and to prevent such incidents.

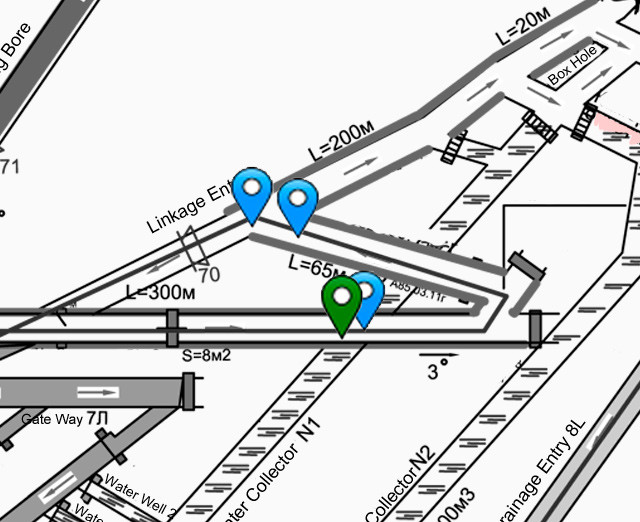

Personnel positioning monitoring in underground mine

An operator can receive data in real-time not only about the positioning of miners and vehicles, but also about the motion path of the monitored objects within certain period of time.

Control of work-time and time spent in a geofence

The RealTrac system enables to register the personnel entry and exit times from a certain geofence. This helps to monitor positioning of personnel in certain zones of a mine and to alert a miner about the need to get to the surface. The data about events is stored in server up to 10 years.

Personnel emergency notifications

In case of emergency, the system sends notifications about evacuation need to all miners. Also, the system enables to use additional warning devices like: sirens, alarm reporting etc.

Personnel detection and evacuation in cases of emergencies

The system provides a real-time control of the evacuation process, while displaying: time spent, personnel motion paths during the evacuation, and what is most important – the system enables to detect positioning of the personnel that couldn’t timely get to safe assembly points.

Key Benefits

Key benefits of the RealTrac Positioning for underground mining:

Enables to meet the legislative requirements and industrial security regulations in underground mining operation

Can use existing underground mine infrastructure

The hardware can be embedded into cap lamp and a miner doesn’t need additional equipment

The modularity of the system enables to add further functionality as required

Due to a single infrastructure, there is a possibility to upgrade a zonal positioning into precise positioning simply by adding additional anchors

Integration by means of the open protocol (API) enables to transmit the data to the HR recordkeeping system, computer-aided process control system etc

Operating principle and the system components

There are two directions of personnel positioning:

Zonal positioning

Detection of personnel or machinery positioning within the accuracy of the zone.

-

Accuracy: typically 20 meters

-

Detection range: up to 100 meters

-

Zone configuration: from 20 meters to *

*The zones are configurable upon Customer’s request. -

Installation expenses: low cost

Precise positioning

Detection of personnel or machinery positioning.

-

Accuracy: typically less than 1 meter

-

Detection range: up to 75 meters

-

Zone configuration: from 5 sq. m.

-

Installation expenses: medium-price

Equipment for personnel and machinery positioning in underground mine

Zone or precise positioning tag – allows to detect objects positioning and notify about danger zone trespassing.

-

Embedded into cap lamp/installed on machinery

-

Power supply from a cap lamp’s battery/ vehicle network battery

-

Does not affect the operation of other reporting systems

-

IP 65, IP 67 rated body, PO Exia I Ma X (optionally)

Anchor is installed in a mine and detects positioning of objects within radio range.

- Is fixed on crossroads and the key zones of a mine.

-

Power supply both line supply (100-240 V) and POE technology

-

Can send the data from tags to the system both in wired and wireless mode

- IP67 rated body, PO Exia I Ma X (optionally)

Software

The RealTrac Positioning software includes server and client.

RealTrac App Server

-

Computing and storing data about the tags positioning

-

Launching on a server based free operating system, not requiring additional licensing.

-

Open protocol (API) for integration with third-party systems

-

Several underground mines and processing plants in one server of the positioning system

RealTrac Web Interface

-

Displaying the current data

-

Analytics and report designer

-

Creating metrics and business-processes based on geofences and other capabilities.

-

Allowing remote access to server (web-based)

More about the product RealTrac Positioning Order the presentation

Key benefits of the RealTrac Underground Mining

-

Capability of integration with dispatch systems and automated control systems for mining and transport operations;

-

Using the existing infrastructure of the mine;

-

Modularity of the RealTrac system enables to extend the functionality as required;

- Integration by means of the open protocol (API) enables to transmit data to HR recordkeeping systems, APCS (Automatic process control system) and others.

Order the presentation RealTrac Underground mine

* - required fields

Address:

RealTrac International

Novi Sad, Serbia, Vase Stajica br.18

Solutions

All solutions

Underground Mining

Open Cast Mining

Production

Logistics

Demokit

Custom development