Proximity detection and positioning system provides personnel and vehicles positioning and allows to trac the objects to minimize the probability of incidents

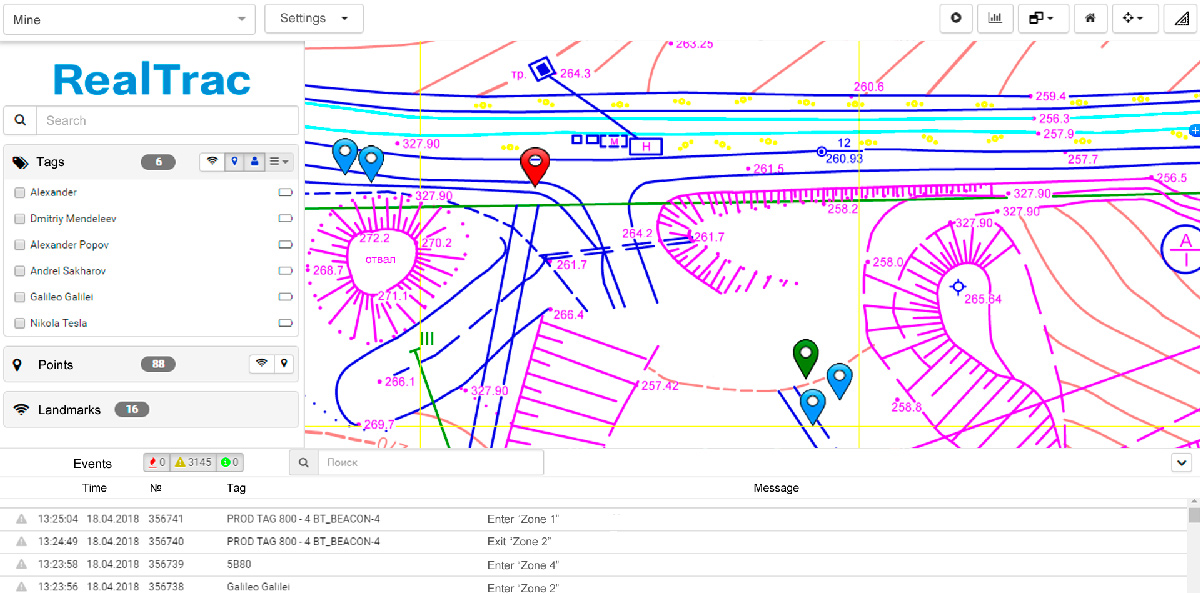

RealTrac "Plant" - A security system for solving problems of ensuring industrial safety requirements at processing industry facilities, plants, factories and other industrial enterprises.

The RealTrac "Plant" solution allows real-time location (positioning) of workers and equipment on the territory of an industrial or processing enterprise, as well as the function of preventing collisions between equipment and personnel.

The RealTrac “Plant” includes the following safety and efficiency increasing products

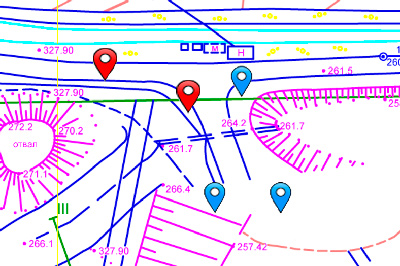

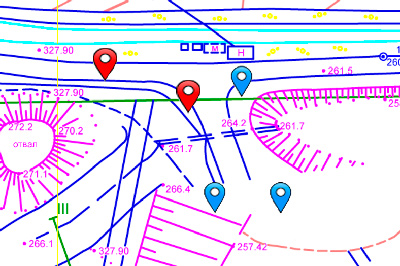

Control of the location of workers on the territory of a quarry or section

The dispatcher can receive real-time data on the current location of all workers or mining equipment, as well as information about the path traveled by the controlled object for a given period.

Worker access control

Thanks to the creation of geofences with different access levels, the dispatcher always knows whether one or another worker is in the permitted or prohibited zone. The reporting and analytics system allows you to identify systematic violations of access levels and prevent possible incidents.

Control of working time, time spent in the geofence

The RealTrac system allows you to register the time of entry /exit of employees in a certain geofence. This allows you to control their presence in certain areas and in areas of work. And also notify the dispatcher or worker if necessary to leave the zone. At the same time, data on movements, time spent in various zones and events are stored on the server for up to 10 years.

Emergency notification of workers during drilling and blasting operations

The system allows real-time monitoring of the process of personnel withdrawal from the hazardous area where drilling and blasting operations are planned. The system also helps with evacuation: the time spent, the trajectories of workers during the evacuation announcement, and most importantly - determining the current location of workers who could not get to safe collection points in time.

Evacuation and detection of workers caught in an accident

The system allows you to monitor the evacuation process in real time: the time spent, the trajectories of the movement of workers during evacuation and, most importantly, determining the current location of workers who could not get to safe collection points in time.

Advantages

Benefits of personnel monitoring in an industrial enterprise:

Modular industrial safety system

Different types of zonal, global positioning and hybrid positioning without drastic changes, thanks to a single infrastructure

Integration using an open protocol (API), allows you to transfer data to personnel accounting systems, automated process control systems and other enterprise systems.

Operating principle and components

Personnel positioning can be carried out in three directions:

Zonal positioning

Determining the location of a worker or equipment with accuracy to the zone.

- Accuracy: +/- 20 meters

- Radio detection range: up to 100 meters

- Zone configuration: from 20 meters to the zone*

* - it is possible to configure zones according to the Customer's request

- Backbone channel: BLE or other data transfer protocol**

* - According to the Customer's requirements

- Restrictions: Work only in the area of radio visibility of access points

- Implementation costs: low

Global positioning

Determining the location of a worker or equipment with an accuracy of up to a meter.

- Accuracy: +/- 1-5 meters

- Radio detection range: unlimited

- Zone configuration: from 10 sq.m.

- Backbone channel: Wi-Fi, LoRa or other data transfer protocol*

* - According to the Customer's requirements

- Restrictions: Work in visibility conditions of at least 4 satellites

- Implementation costs: low

Hybrid positioning

Combines the advantages of zonal and global positioning.

- Accuracy: +/- 1-5 (20) meters

- Detection range: unlimited

- Zone configuration: from 10 sq.m.

- Backbone channel: Wi-Fi, LoRa or other data transfer protocol*

* - According to the Customer's requirements

- Restrictions: Zonal positioning works indoors. Global positioning works in an open area

- Implementation costs: average

Equipment for monitoring the location of workers and equipment on the territory of open-pit mining:

Personal tag / Transport tag – allows you to determine the location and notify about entering the danger zone.

- Designed as a separate device / installed on machinery

- Powered by battery / on-board network of mining equipment

- Does not affect the operation of other notification systems

- Enclosure protection class IP 65, IP 67, PO Exia I Ma X (Optional)

Access point – installed in places where zonal positioning is required and provides monitoring of objects in the radio visibility zone.

- It is installed in areas where zonal positioning is required

- Power supply, both from the electrical network (100-240V) and using POE technology

- It can transmit data from tags to the system, in wired mode

- Enclosure protection class IP67

Software

The RealTrac Positioning product includes server and client software.

RealTrac Server

- Calculation and storage of tag location information

- Running on a server running free software and does not require additional licensing

- Availability of an open protocol (API) for integration with third-party systems

- Several quarries and processing plants on one positioning system server

RealTrac Client

- This client, does not require the installation of additional software on the workplace of the dispatcher or manager

- Visualization of current data

- Analytics and Report Builder

- Creating metrics and business processes based on geofences and other system features

- Differentiation of employee access levels for working with the web interface of the positioning system

- Ability to connect to a remote server

More about the product RealTrac Positioning Solution presentation request

RealTrac Collision Awareness

The product is designed to reduce the number of accidents associated with a collision of vehicles and machinery, as well as collisions of vehicles with workers in conditions of insufficient or poor visibility.

Tasks to be solved

The product solves problems in two directions of control:

Direction: Vehicle - vehicle (V2V)

Tasks

- Improving the safety of the movement of quarry transport in conditions of poor or insufficient visibility

- Reduction of costs associated with downtime and repair of quarry equipment as a result of a collision

Functions

- Fixing the fact of dangerous proximity of vehicles and mining equipment

- Notifying the driver/worker or operator about the possibility of a collision

Direction: Vehicle - personnel (V2P)

Tasks

- Helps to reduce the level of injuries associated with the impact of mining equipment on people

- Allows you to make safe maneuvers of quarry fleet with several people around it

Functions

- Fixing the fact of a dangerous incident related to hitting a worker

- Notification of the worker's presence in the danger zone for the vehicle operator and for the person in a same time

Advantages of preventing collisions between vehicles and with workers

What distinguishes the RealTrac Collision Prevention product from analogues:

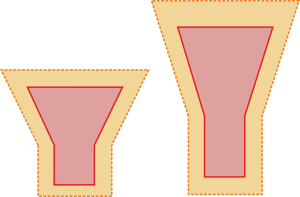

360 degree control around the vehicle

Determining the distance and direction to another object with an accuracy of 0,2 meter

Three control zones with the ability to set them any size and configuration

Сontrol zones around the quarry equipment, adjustable depending on the dimensions of the equipment or the position of the working mechanism of any special fleet

Full autonomy of the system (Access to GPS and GSM signal is not required for operation)

Operating principle and components

Provides a situational understanding of the environment around the vehicle, identifying the presence of vehicles, people or objects inside previously defined zones. As soon as an object, vehicle or employee equipped with a collision awareness system tag approaches previously defined zones, the system issues a tangible, audible and visible warning.

The notification can be sent using:

Sound notification from the equipment, the inclusion of sirens or beeps

Vibration from a personal tag

Light notification from a personal tag

Flashing of the headlights of the equipment or the inclusion of other visual warning devices

The intensity of the alert can be adjusted depending on the control zone.

Equipment for workers

Personal tag (tracker) PROD TAG 720 or PROD TAG 210 - is issued to the worker and with its help the location relative to the vehicle with the installed antennas of the collision prevention system is determined. The tag is made in the form of a separate wearable device.

Equipment for vehicles

The display is installed in the driver's cab and serves for visual assessment of the situation around the vehicle, receiving alerts about a dangerous approach and monitoring the status of the system.

The control unit is installed on the transport and calculates the distance from the tag to the antennas and the direction of movement of the tag. Determines which of the control zones the tag is located in and, depending on this, displays information about objects in different zones on the driver's display and includes light-graphic or sound warning signals.

The antenna is installed in an amount of 4-6-8 pieces, depending on the size and configuration of mining equipment and is used to detect personal tags (trackers) or antennas installed on other equipment.

Autonomous operation mode

The system has built-in software and has absolute autonomy from other systems and the data transmission network.

When implementing a backbone channel, the system can transmit data on recorded dangerous approaches, collisions and other information to the RealTrac system server. This allows for the subsequent analysis of incidents and the construction of work report.

More about the product RealTrac Collision Awareness System Solution presentation request

Benefits of the RealTrac Plant

- Possibility of integration with dispatching and control systems of the mining and transport complex and other enterprise systems

- Leverages existing mining infrastructure

- The modularity of the RealTrac system allows you to add functionality as needed

- Integration using an open Protocol (API)

Products from RealTrac Technologies today are:

900+

Number of trackers used in Plant

10+

Number of equipped Plant

Order presentation of the RealTrac “Plant”

* - required fields

Address:

RealTrac International

Novi Sad, Serbia

Solutions

All solutions

Underground Mining

Open Cast Mining

Production

Logistics

Demokit

Custom development